Ransohoff Industrial Parts Washer FAQs

Cleaning Technologies & System Capabilities

A portable industrial parts cleaning system is a self-contained washer designed for mobility and flexibility in cleaning parts at multiple workstations or production areas.

Ransohoff designs its portable systems with rugged stainless-steel construction, ergonomic mobility features, and plug-and-play operation. These units combine powerful aqueous cleaning technology with compact footprints, making them ideal for maintenance teams, field service operations, and limited-space manufacturing environments. Many models can be customized with filtration, heat, and ultrasonic cleaning to deliver precision results wherever they’re needed.

Ransohoff’s cabinet ultrasonic washers deliver a higher level of precision cleaning than traditional spray cabinets by combining ultrasonic cavitation with aqueous chemistry.

While spray cabinets rely on high-pressure jets to remove surface contaminants, ultrasonic washers use microscopic bubbles that implode on the part’s surface, removing oils, fine particles, and residues from complex geometries and blind holes. The result is superior cleanliness, faster cycle times, and reduced chemical consumption, especially for components with intricate features or tight tolerances.

Industrial ultrasonic consoles from Ransohoff offer greater capacity, power, and process control than bench-top or immersion-style washers.

These floor-mounted systems are designed for production-scale cleaning, providing features such as automated agitation, precision temperature control, multi-tank configurations for rinse and dry stages, and advanced filtration. The result is consistent, repeatable cleanliness for demanding industries like aerospace, medical, and automotive, where small bench systems often fall short in throughput or validation requirements.

Ransohoff’s ultrasonic parts washers are engineered for maximum energy efficiency through intelligent power management, optimized tank insulation, and advanced ultrasonic transducer technology.

By focusing ultrasonic energy precisely where it’s needed, these systems minimize wasted power while maintaining excellent cleaning results. Aqueous solutions can often be filtered and reused, further reducing energy and water consumption, helping facilities meet sustainability goals without compromising on cleaning performance.

Choosing between an aqueous washer and an ultrasonic system depends on part complexity, contamination type, and cleanliness requirements.

- Aqueous spray washers are ideal for robust parts with heavy oils, chips, or surface soils that respond well to mechanical spray action.

- Ultrasonic washers excel with delicate or intricate components that require gentle yet thorough cleaning, such as medical instruments, precision machined parts, or electronics.

Ransohoff’s engineering team can evaluate your parts and contamination profile to recommend the most efficient and cost-effective system for your application.

Click here to fill out a contact form and let us determine what is needed to meet your expectations.

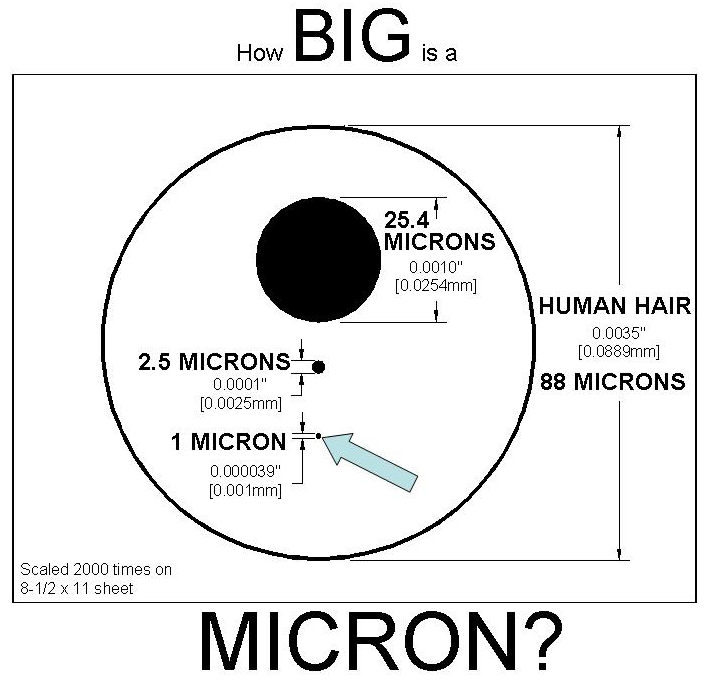

View the diagram How Big is a Micron?

Applications, Performance & Compliance

Yes. Ransohoff’s mobile precision cleaning systems are frequently deployed in automotive manufacturing environments for both production and maintenance applications.

They’re ideal for cleaning parts such as fuel injectors, transmission components, and hydraulic assemblies, especially during line changeovers or maintenance tasks. Their mobility allows technicians to bring the cleaning system directly to the work area, minimizing downtime and maintaining part cleanliness standards required for modern automotive assembly lines.

In food and beverage facilities, ultrasonic cleaning stations from Ransohoff enhance hygiene and operational reliability by removing buildup that conventional cleaning methods often miss.

Ultrasonic cavitation reaches inside small crevices and hard-to-clean surfaces found on filling nozzles, valves, and processing equipment, helping eliminate residues, oils, and contaminants without harsh scrubbing. This improves equipment performance, supports regulatory compliance, and reduces the risk of product contamination, all while minimizing labor and water use.

Aerospace applications demand strict adherence to cleanliness validation, safety, and process documentation.

Ransohoff’s industrial ultrasonic consoles are built to comply with relevant aerospace standards, including those governing solvent replacement, aqueous chemistry compatibility, and cleanliness verification (e.g., MIL-STD-1246C). Systems can be equipped with safety interlocks, vapor containment, chemical monitoring, and automated record-keeping, ensuring compliance with both aerospace OEM specifications and environmental regulations.

For remote or field service work, choose a mobile ultrasonic parts washer that is durable, easy to transport, and capable of operating independently.

Key features include stainless-steel construction, built-in fluid filtration and recycling, adjustable ultrasonic power, integrated heating, and compatibility with available power sources. Ransohoff’s mobile systems are designed with these needs in mind, offering dependable cleaning performance in environments where stationary equipment isn’t practical.

In high-throughput operations, maintaining a Ransohoff cabinet ultrasonic washer typically involves scheduled inspections, solution management, and filter replacement.

Operators should monitor solution clarity, check transducer performance, and clean tanks regularly to prevent residue buildup. Automated filtration systems and oil skimmers can extend bath life and reduce manual maintenance. Ransohoff designs its systems with easy access to service components, minimizing downtime and simplifying upkeep.

Evaluation, Cost & Ongoing Support

Any washer proposal that we prepare can be provided with a LCC Analysis at no cost.

We would prefer that you allow us the opportunity to test actual production parts prior to placing an order. This gives us a chance to prove our process and give you piece of mind that you are making an educated purchase. You will be provided with a formal test report summarizing the exact process and test parameters used. We also take this opportunity to review the makeup of your waste stream to determine if recycling your cleaning solution and possibly your cutting fluids using one of our ultrafiltration systems is possible.

We do offer service contracts for maintaining one or multiple parts washers in your facility. Keep in mind that it is not necessary that they are Ransohoff or Blackstone-NEY washers. We routinely provide rebuild and retool services for our competitor’s machines. Energy audits are available and highly recommended as there are many low cost ways to reduce energy consumption by your parts washers.

We have service teams available around the clock in both North American and Asia. You can expect a return call usually within a few hours and, in most cases, corrective action with 24 hours. As we always build from our platform products, parts are readily available.