FAQs

Industrial Parts Washers FAQs

Any washer proposal that we prepare can be provided with a LCC Analysis at no cost.

We would prefer that you allow us the opportunity to test actual production parts prior to placing an order. This gives us a chance to prove our process and give you piece of mind that you are making an educated purchase. You will be provided with a formal test report summarizing the exact process and test parameters used. We also take this opportunity to review the makeup of your waste stream to determine if recycling your cleaning solution and possibly your cutting fluids using one of our ultrafiltration systems is possible.

We do offer service contracts for maintaining one or multiple parts washers in your facility. Keep in mind that it is not necessary that they are Ransohoff or Blackstone-NEY washers. We routinely provide rebuild and retool services for our competitor’s machines. Energy audits are available and highly recommended as there are many low cost ways to reduce energy consumption by your parts washers.

We have service teams available around the clock in both North American and Asia. You can expect a return call usually within a few hours and, in most cases, corrective action with 24 hours. As we always build from our platform products, parts are readily available.

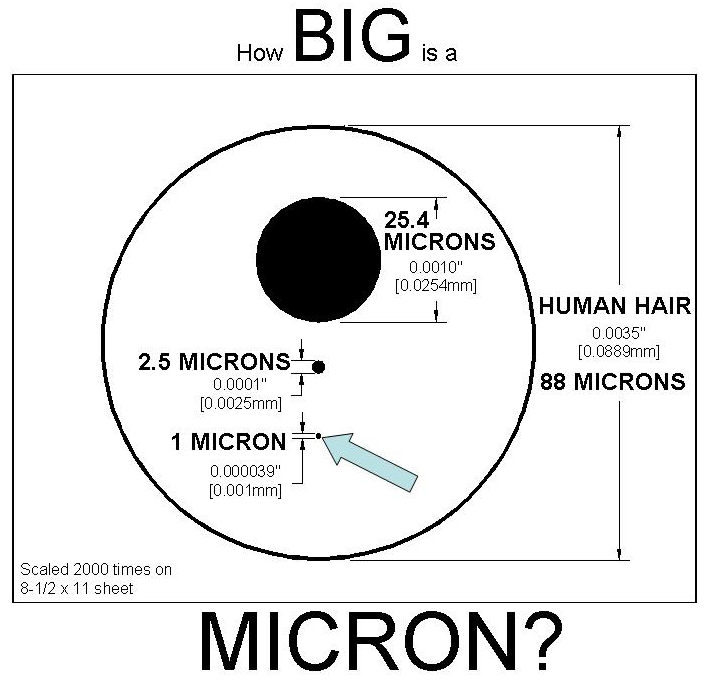

View the diagram How Big is a Micron?

Click here to fill out a contact form and let us determine what is needed to meet your expectations.